Syndustry MES

Verhoog je efficiëntie

met onze

Manufacturing

Execution

Systems

op maat.

Streamline your production processes and improve output with advanced real-time insights.

Trusted by leading organisations.

Our solutions are used by industry leaders.

Efficiency in the Forefront.

Enhance your operational efficiency with Syndustry MES: quick to deploy, easy to integrate, and strong in performance.

Verhoog je Operationele Efficiëntie.

Syndustry MES automates and optimizes production processes, reduces manual errors, and increases throughput. Experience seamless operations with real-time monitoring and control, ensuring maximum productivity with minimal downtime.

Verlaag je kosten en verhoog je ROI.

Verlaag operationele kosten door verspilling te minimaliseren en downtime te reduceren. Syndustry MES verbetert het beheer van middelen, waardoor je je investeringen sneller terugverdient door optimalisatie van materiaalgebruik en energieverbruik.

Laat Je Operaties Meegroeien met Jouw Ambities.

Easily scale your operations with Syndustry MES. Our system grows with your business and smoothly adapts to new challenges and expanding production requirements, without the need for extensive reconfiguration.

MES Features that Enhance Your Production.

Boost your operational efficiency with Syndustry MES: rapidly deployable, easy to integrate, and extremely powerful. Discover how our specialized capabilities can improve your production processes.

Plan voor maximale productie efficiëntie.

Production Sequence Optimization

Accelerate your production by optimizing the order sequence to achieve maximum efficiency and minimal wait times, leveraging advanced algorithms and real-time data.

Capacity Planning

Enhance your production capacity through precise and dynamic scheduling of people, machines, and materials, tailored to evolving production demands and unexpected events.

Order Management

Efficiently manage your production orders from acceptance to delivery with integrated tracking tools that shorten lead times and enhance transparency. Real-time monitoring for unmatched production control.

Real-time monitoring voor ongeëvenaarde productiecontrole.

WIP (Work in Progress) Tracking

Gain detailed insights into all work-in-progress items to efficiently identify and resolve bottlenecks, ensuring a streamlined production flow.

Quality control

Ensure consistent product quality with integrated quality control mechanisms that accurately detect and correct deviations, embedded at every stage of the production line.

Real-time Status Updates

Stay continuously informed about the production status with live updates, enabling you to promptly respond to process disruptions and boost operational efficiency.

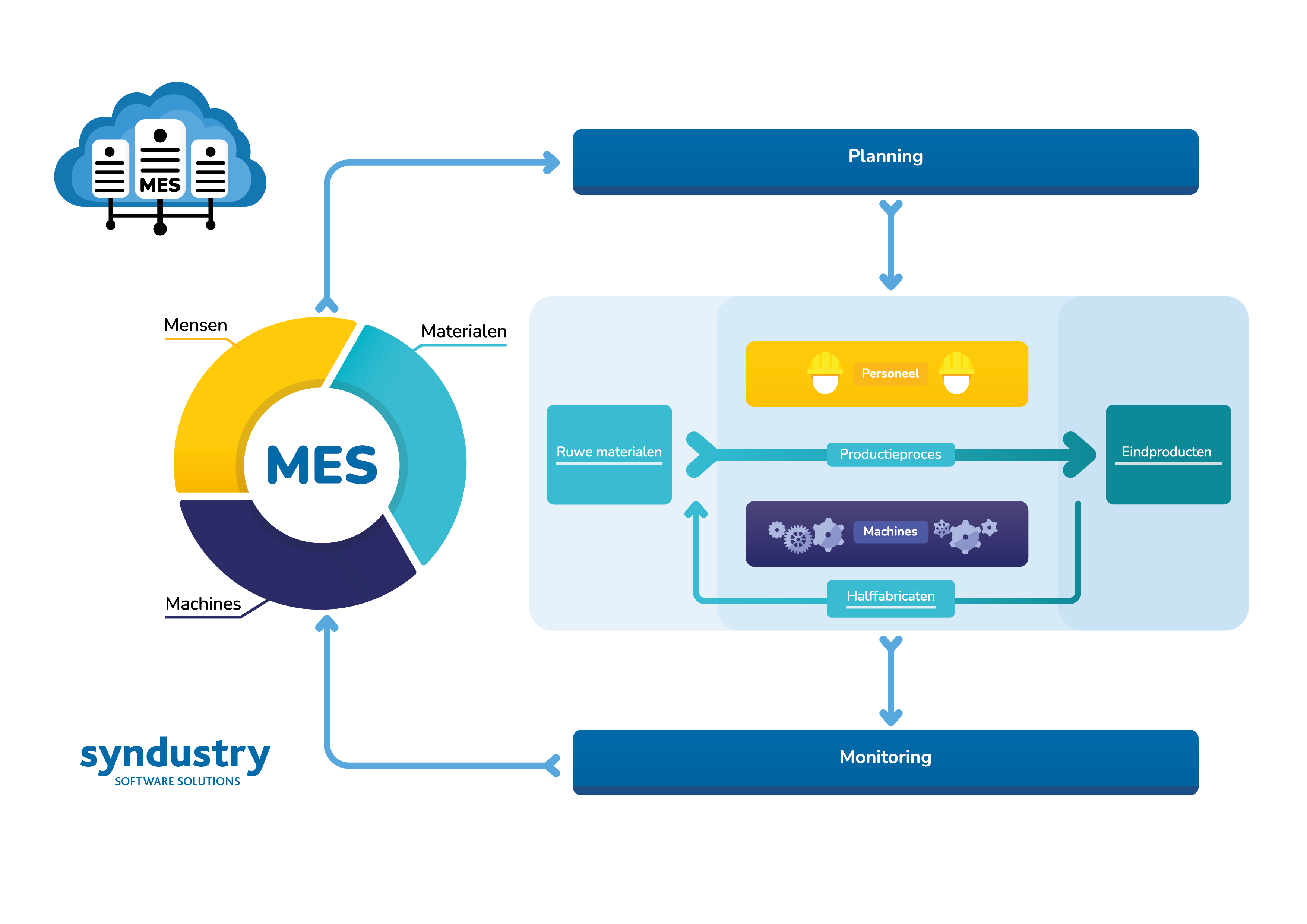

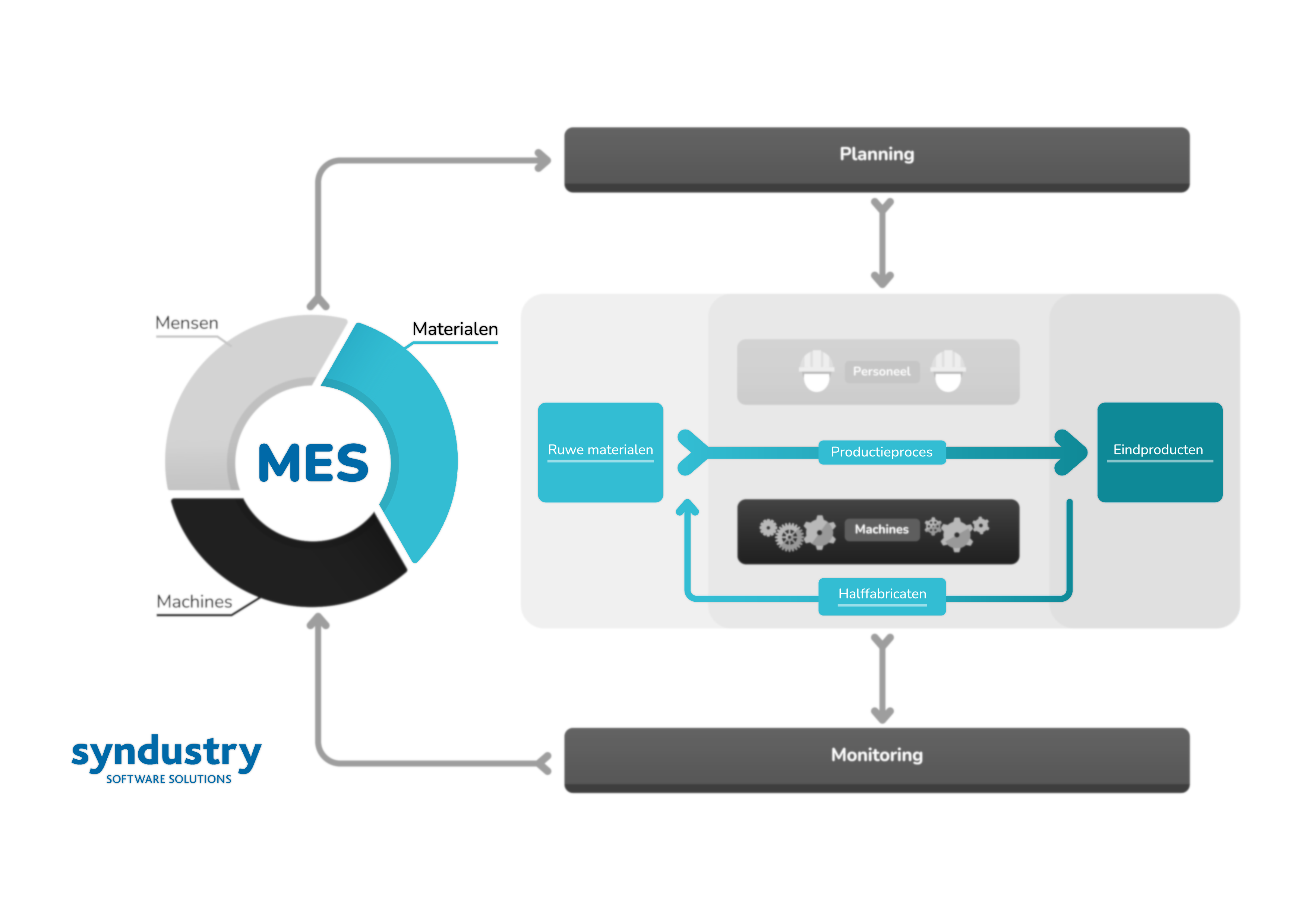

Syndustry MES: the hub of your production.

An integrated approach from planning to sales.

Syndustry MES optimizes your production process with powerful planning and real-time monitoring, connecting people, materials, and machines for unparalleled efficiency from start to finish.

Core Features: Planning and Monitoring.

At the core of our MES, the modules for planning and monitoring ensure a continuous and efficient production flow, heavily reliant on real-time data and strategic production scheduling.

Planning: The Foundation of Efficient Manufacturing.

Centraal in het Syndustry MES staat de planningsmodule, die essentieel is voor de dagelijkse productiecoördinatie. Deze component helpt bij het opstellen van gedetailleerde productieschema’s, die nauwkeurig de inzet van machines en personeel reguleren. Het verzekert dat de beschikbare middelen effectief worden toegewezen om aan de productievereisten te voldoen. De planningsmodule richt zich op het maximaliseren van de productie-efficiëntie door de beschikbare capaciteit en productieorders op elkaar af te stemmen. Het resultaat is een gestroomlijnde productieflow waarbij elk aspect van het productieproces, van orderontvangst tot eindproduct, wordt geoptimaliseerd.

Monitoring: Immediate Insight and Oversight.

De monitoringfunctie van het Syndustry MES biedt je een real-time blik op de productieactiviteiten. Deze tool stelt je in staat om continu de prestaties van productieprocessen en machines te volgen en te controleren. Met real-time updates en alerts kun je direct reageren op eventuele afwijkingen of verstoringen. De informatie wordt tevens teruggekoppeld naar de planning. Dit verhoogt niet alleen de efficiëntie maar zorgt ook voor het behoud van de productiekwaliteit door proactief beheer en aanpassingen waar nodig.

Supportive MES Modules.

Beyond the core capabilities of planning and monitoring, our MES includes specialized modules — People, Machines, and Materials — each uniquely designed to enhance and support production efficiency. These modules facilitate deep integration and optimization of critical production components, refining and streamlining each phase of the production process.

Syndustry People: Maximum Efficiency in Personnel Management.

Syndustry Mensen optimaliseert het beheer van je personeel door elke werknemer efficiënt in te zetten. Het systeem biedt tools voor het beheren van roosters, het volgen van vaardigheden en certificaties, en het analyseren van de werkprestaties. Dit verzekert dat je over de juiste persoon beschikt op de juiste plek en tijd, afgestemd op de specifieke eisen van het productieproces. Door real-time data te leveren over personeelsinzet, helpt ons MES je om proactief te reageren op veranderende productieomstandigheden, terwijl het welzijn van je werknemers gewaarborgd blijft.

Read more…

Syndustry Machines: Optimization of Machine Performance and Maintenance.

Syndustry Machines zorgt voor een naadloze integratie van machinebeheer en onderhoudsplanning. Het houdt real-time de prestaties en de status van elke machine bij, waardoor preventief onderhoud mogelijk is voordat storingen optreden. Dit minimaliseert downtime, verhoogt OEE en verlengt de levensduur van je apparatuur. Onze oplossingen gebruikt geavanceerde data-analyse om de efficiëntie van machines te optimaliseren, waardoor je productiekosten verlagen en de output kwaliteit verhoogt.

Read more…

Syndustry Materials: Intelligent Management of material resources and Inventories.

Waarborg een gestroomlijnde beheer van materialen van inkoop tot productie. Syndustry Materialen regelt de opslag, het gebruik, en de herbevoorrading van grondstoffen en halffabrikaten, waardoor je nooit te veel of te weinig op voorraad hebt. Dit verhoogt de efficiëntie en vermindert verspilling door ervoor te zorgen dat materialen precies op tijd beschikbaar zijn voor het productieproces. Bovendien biedt het MES inzicht in materiaalverbruikspatronen, wat helpt bij toekomstige planning en kostenreductie.

Read more…

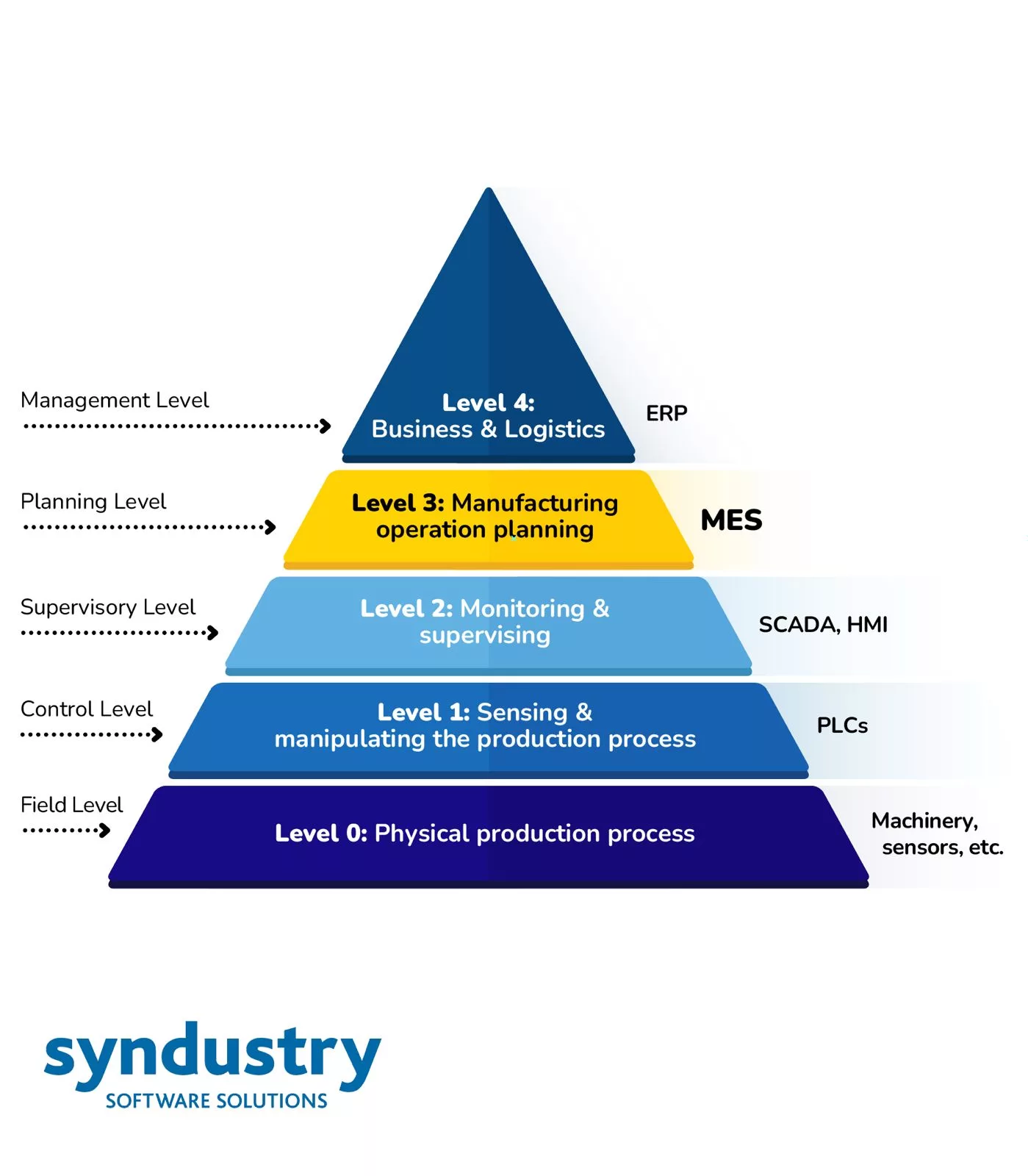

Integration of MES into the ISA-95 Industrial Automation Hierarchy.

The Manufacturing Execution System (MES) is a core component of the ISA-95 automation standard, serving as a crucial connecting layer between enterprise management and production execution. MES systems synchronize production information in real-time, coordinate production activities, and ensure data integrity across the entire production chain.

Level 4: The highest layer where ERP systems manage and align general business and logistics processes with actual production capabilities.

Level 3: Syndustry MES is at the heart of production, supporting and executing production orders. It manages production tracking, quality management, maintenance, and collects and documents all production-related information.

Level 2: At this level, SCADA (Supervisory Control and Data Acquisition) and HMI (Human Machine Interface) oversee, monitor, and allow adjustments to production activities for operational efficiency.

Level 1: This level includes control systems such as PLCs (Programmable Logic Controllers) that regulate direct machine functions and monitor process variations.

Level 0: The fundamental level of the production process where direct interaction with production equipment occurs.

Syndustry MES is rooted in the principles of ISA-95, ensuring a seamless integration of production control and business strategy. This creates a flexible, transparent, and efficient production environment where every part of the production process is optimized.

Discover the impact of Syndustry MES on your production process. Contact us for a consultation with our experts.

Schedule now a introduction meeting with Joep

Are you ready to discover what Syndustry MES can do for your production? Schedule a personal meeting with me to discuss your unique needs and our solutions.

Choose your most convenient time below and take the first step towards more efficient production.

Frequently asked questions about a personal appointment:

What can I expect from a meeting with Joep?

During a personal conversation, we'll discuss your current production processes and explore together how Syndustry MES can optimize them. You will gain insights into the functionalities and benefits of our solution, specifically tailored to your situation.

How long does a typical meeting take?

A typical meeting takes about 30 minutes. We ensure enough time to answer your questions and give a clear picture of the possibilities with our MES.

Should I prepare for the meeting?

It would be helpful if you have some information about your current processes at hand, but it is not necessary. We can also help you gather the relevant information during the meeting.

Are there any costs associated with the meeting?

No, this appointment is completely non-binding and free of charge. It is an opportunity for you to learn more about our MES and what we can do for your business.

Bekijk ook onze ondersteunende modules:

Bij Syndustry begrijpen we dat een soepel en efficiënt productieproces afhankelijk is van verschillende elementen. Naast ons uitgebreide MES, bieden we ook ondersteunende oplossingen aan voor het beheer van jouw Mensen, Machines en Materialen.

Syndustry Mensen:

Optimaliseer je personeelsbeheer en verhoog de productiviteit met slimme planning en real-time inzicht in personeelsinzet.

Read more…

Syndustry Machines:

Houd je machines in topconditie en voorkom onverwachte storingen met ons uitgebreide machinebeheer.

Read more…

Syndustry Materialen:

Zorg voor een efficiënt en nauwkeurig voorraadbeheer, en verminder verspilling met onze materiaalbeheeroplossingen.

Read more…

Ontdek hoe onze modules jouw productie naar een hoger niveau kunnen tillen. Neem vandaag nog contact met ons op voor meer informatie.