Syndustry Machines

Efficiency at the Forefront: Discover our machine management solutions.

Smartly control your machinery, enhance efficiency, and reduce downtime.

Maximise Machine Efficiency.

Discover how Syndustry Machines reduces unplanned downtime and enhances the efficiency and reliability of your production line.

Prevent Breakdowns

Benefit from our advanced sensor technology that continuously monitors your machines to detect potential critical issues before they cause outages. This early warning system enables you to plan proactive maintenance without disrupting production, significantly improving operational reliability and machine lifespan.

Optimise Machine Performance

Increase operational efficiency with our integrated machine management platform that continuously collects and analyses data. Utilising real-time monitoring and advanced analytics tools, you can not only optimise the performance of each machine but also reduce energy consumption and shorten the overall duration of production processes, directly contributing to higher productivity.

MAXIMISE CAPACITY

Enhance your machines' capacity utilisation with our advanced insights into occupancy rates and seamless integration with other Syndustry modules. Our systems provide real-time data analysis, optimising operations and increasing throughput. This leads to more efficient machine deployment and strong alignment between machines, people, materials, and processes.

Trusted by leading organisations.

Our solutions are used by industry leaders.

Core Features of Syndustry Machines.

At the heart of Syndustry Machines are innovative features specifically designed to maximise the performance of your production lines. Explore the capabilities of our solutions that not only increase the operational capacity of your machines but also extend their lifespan. Below, we present the core features that make Syndustry Machines an essential addition to your production environment:

Industrial Internet Of Things (IIOT)

Verbeter je operationele efficiëntie met Industrial Internet Of Things (IIOT). Door een directe verbinding met SCADA-systemen (Supervisory Control and Data Acquisition) biedt deze functie een naadloze stroom van realtime gegevens van je machinepark.

Real-Time Machine Monitoring

With our real-time monitoring tools, keep a constant watch on your machines. Instantly notice any deviation from the norm, allowing you to intervene swiftly before real problems occur.

Performance Analysis and Reporting

Gain deep insights into your machines' performance with our detailed analysis and reporting tools. Quickly identify efficiency opportunities and transform data into action.

Predictive Maintenance

Prevent unplanned downtime with our predictive maintenance features. Our system analyses operational data and predicts when maintenance is needed, allowing you to optimise maintenance schedules and extend the lifespan of your machines.

Energy Management

Manage your energy consumption more efficiently with our energy management tools. Reduce your energy costs and increase the sustainability of your production processes through smart energy usage.

User-Friendly Interface

Our interface is designed for ease and user-friendliness. Even if you are not a technician, you can easily navigate our software, saving you time and keeping your focus on what’s truly important – your production."

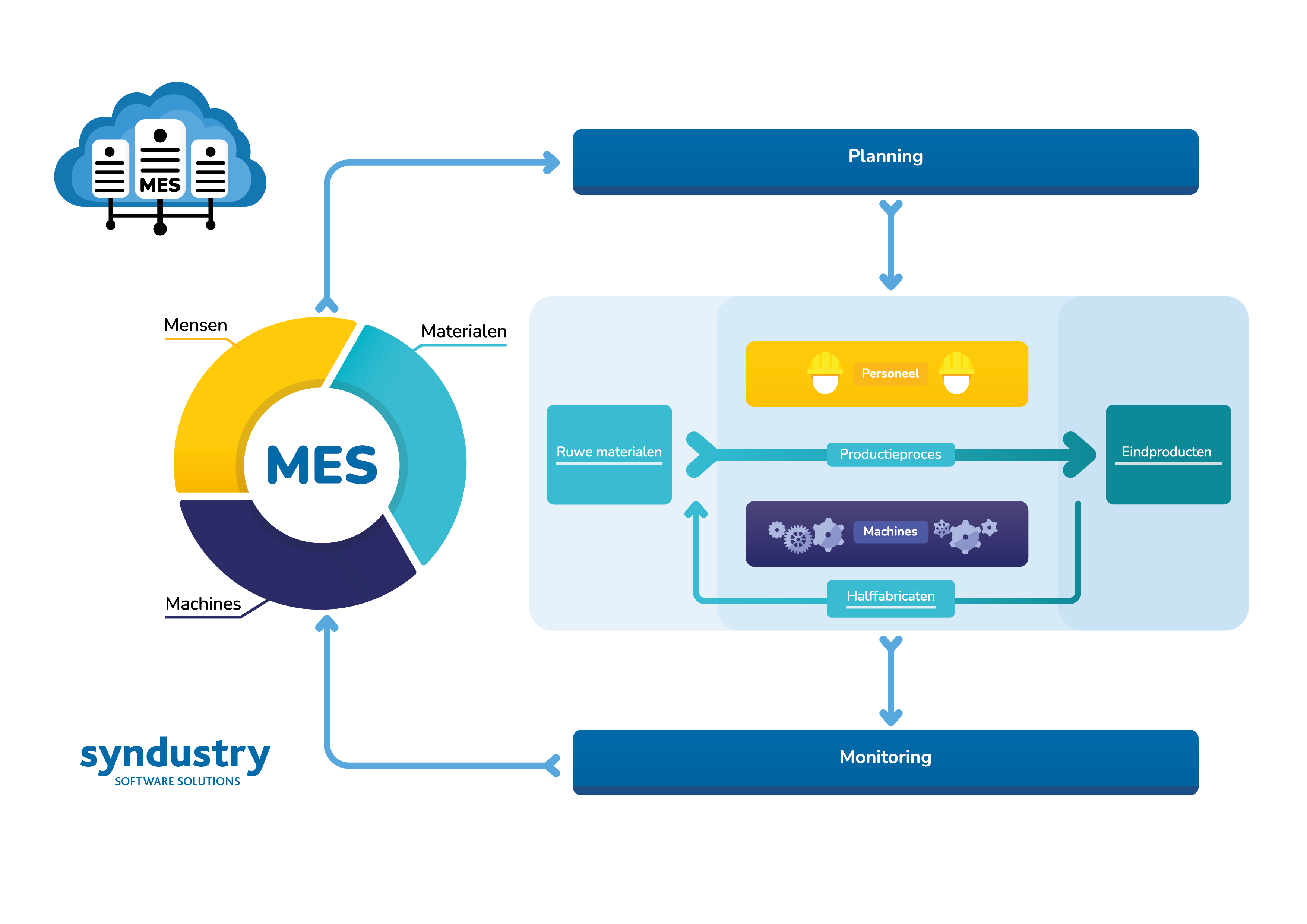

Integration with Syndustry MES: The Hub of Your Production.

An integrated approach from planning to sales.

Integrating with Syndustry MES allows you to experience a seamlessly orchestrated production process, where the interaction between People, Materials, and Machines is central. Syndustry People is designed to act as a pivot within this complex network, elevating your production efficiency to new heights. Discover how this profound integration optimises every aspect of your operations, from personnel management to machine maintenance and material logistics, ensuring a streamlining essential for modern, high-quality production facilities.

Syndustry MES: Planning and Monitoring.

At the heart of our MES, the planning and monitoring modules facilitate a seamless production flow, centred on real-time data and efficient production planning.

Planning: The Foundation of Efficient Manufacturing.

The planning module is pivotal in Syndustry MES, crucial for managing daily production activities. This element aids in devising precise production schedules, meticulously managing the utilization of both machinery and personnel. It guarantees the optimal allocation of resources to satisfy production demands. The planning module aims to enhance production efficiency by synchronizing the available capacity with production orders, resulting in an optimized production process from the initial order to the final product.

Lees meer…

Monitoring: Immediate Insight and Oversight.

Syndustry MES's monitoring capability provides an instantaneous overview of ongoing production activities. This feature allows for the ongoing assessment and supervision of production processes and equipment. Thanks to instant updates and notifications, you can react swiftly to any irregularities or interruptions. Additionally, this information is relayed back to the planning stage, boosting not only efficiency but also sustaining product quality through proactive oversight and necessary adjustments.

Lees meer…

Our supportive MES Modules.

Beyond the core capabilities of planning and monitoring, our MES includes specialized modules — People, Machines, and Materials — each uniquely designed to enhance and support production efficiency. These modules facilitate deep integration and optimization of critical production components, refining and streamlining each phase of the production process.

Syndustry People: Maximum Efficiency in Personnel Management.

Syndustry People optimizes staff management by efficiently allocating each employee. The system provides tools for managing schedules, tracking skills and certifications, and analyzing work performance. This ensures you have the right person in the right place at the right time, tailored to the specific demands of the production process. By delivering real-time data on personnel deployment, our MES helps you proactively respond to changing production conditions while ensuring the well-being of your employees.

Lees meer…

Syndustry Machines: Optimization of Machine Performance and Maintenance.

Syndustry Machines enables seamless integration of machine management and maintenance scheduling. It monitors the performance and status of each machine in real-time, facilitating preventive maintenance before failures occur. This minimizes downtime, enhances OEE, and extends the lifespan of your equipment. Our solutions use advanced data analysis to optimize machine efficiency, reducing production costs and improving output quality.

Syndustry Materials: Intelligent Management of material resources and Inventories.

Ensure streamlined management of materials from procurement to production. Syndustry Materials manages the storage, usage, and replenishment of raw materials and semi-finished products, ensuring you never have too much or too little in stock. This increases efficiency and reduces waste by ensuring materials are available just in time for production. Additionally, the MES provides insights into material consumption patterns, aiding future planning and cost reduction.

Lees meer…

Schedule now a introduction meeting with Joep

Are you ready to discover what Syndustry MES can do for your production? Schedule a personal meeting with me to discuss your unique needs and our solutions.

Choose your most convenient time below and take the first step towards more efficient production.

Frequently asked questions about a personal meeting:

What can I expect from a meeting with Joep?

During a personal conversation, we'll discuss your current production processes and explore together how Syndustry MES can optimize them. You will gain insights into the functionalities and benefits of our solution, specifically tailored to your situation.

How long does a typical meeting take?

A typical meeting takes about 30 minutes. We ensure enough time to answer your questions and give a clear picture of the possibilities with our MES.

Should I prepare for the meeting?

It would be helpful if you have some information about your current processes at hand, but it is not necessary. We can also help you gather the relevant information during the meeting.

Are there any costs associated with the meeting?

No, this appointment is completely non-binding and free of charge. It is an opportunity for you to learn more about our MES and what we can do for your business.

Explore Our Other Solutions:

Enhance your factory’s production planning and control with Syndustry’s software solutions. Streamline operations, optimize resources, and achieve efficient workflows with our advanced tools. Gain control and visibility to thrive in today’s dynamic production landscape.

Capacity Planning

Schedule people and machines, track production progress in real time, and gain live insights into your production activities.

Material Requirement Planning

Monitor your current and projected inventory in real time. Make informed decisions about future material needs.

Shop Floor Control

Go paperless and automate the communication of the latest order information to the shop floor, digitally record human and machine hours, and gain real-time insights into order progress.